Size it

Almost half of all our milk spoilage claims are due to plant failure.

SO ensure the chiller is the right size for your operation. If your milk solids have increased, you may need to up-size the chiller. Off-season maintenance is important to check your chillers are working correctly.

Stand Out

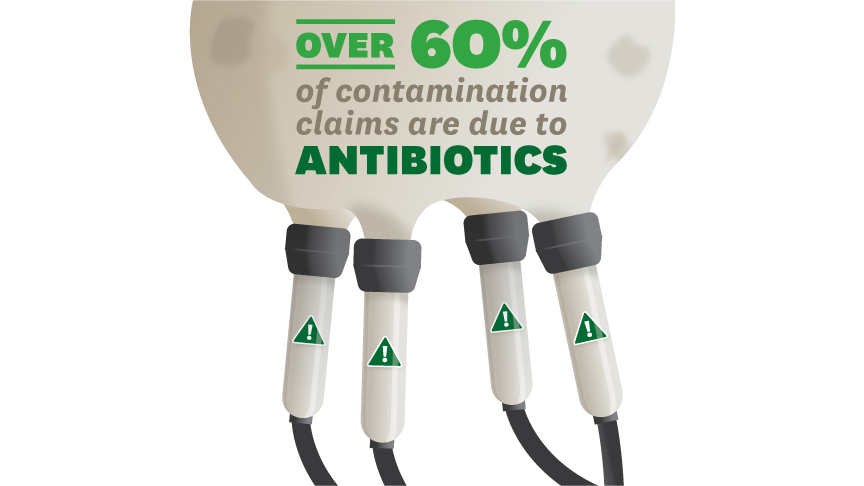

Antibiotic contamination occurs throughout the year, but FMG milk contamination claims peaks early in the season – when mastitis and antibiotic use is most frequent. DairyNZ’s MRS T process is best practice for avoiding milk contamination from antibiotics.

Have a backup generator ready

Power failure can have a major impact on your ability to both milk and refrigerate milk at the required temperature. Having a contingency plan, including a backup source of power will help minimise disruption during the season.

Avoid spoilage - switch on your vat

Order your free milk vat sticker here for a reminder to make sure the power's on.